Industry Knowledge Extension

Brazing alloys are materials used to join two or more pieces of metal together through the process of brazing. Brazing is a joining technique that uses heat and a filler metal that has a melting point lower than that of the base metals being joined. The filler metal is heated until it melts and flows between the two metal surfaces to be joined, creating a strong, permanent bond.

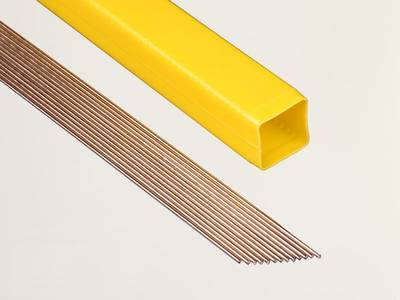

There are many different types of brazing alloys available, each with unique properties and characteristics. The most common types of brazing alloys are made from copper, silver, nickel, and aluminum, and they may contain various other elements, such as zinc, manganese, or phosphorus, to enhance their performance. Brazing alloys are available in many forms, including wire, rod, foil, and preformed shapes.

The choice of brazing alloy depends on the specific application and the properties required of the joint, such as strength, corrosion resistance, and temperature resistance. For example, copper-phosphorus brazing alloys are commonly used for joining copper and copper alloys, while silver brazing alloys are often used for joining stainless steel, nickel alloys, and other high-strength metals.

It is important to select the right brazing alloy and to follow proper brazing techniques to ensure a strong and reliable joint.

Brazing alloys are used to join two or more metal components by heating the joint area to a temperature above the melting point of the brazing alloy, but below the melting point of the base metal. The melted brazing alloy is then drawn into the joint by capillary action, and solidifies, forming a strong and permanent bond.

The main role of brazing alloys is to act as a filler material to fill the gap between the metal components being joined. The choice of brazing alloy is crucial, as it needs to have a lower melting point than the base metal, and it should also have good wetting properties to ensure it can flow and spread evenly into the joint.

Brazing alloys are used in a wide range of industries, including aerospace, automotive, construction, and electronics. They can be used to join dissimilar metals, such as copper and steel, and are often preferred over welding due to the ability to join materials with different melting points, without causing distortion or other damage to the base metal.

Overall, brazing alloys play a crucial role in the manufacturing and repair of a wide range of metal components, enabling strong and durable bonds to be created between different materials.

Brazing alloys are materials used to join metal parts by heating the alloy to a temperature higher than the melting point of the alloy but lower than the melting points of the parts being joined. The alloy then flows between the parts and solidifies, creating a strong and permanent bond. Here are some characteristics of brazing alloys:

Melting Point: The melting point of brazing alloys is generally lower than the melting points of the metals being joined. This allows the brazing process to be carried out without damaging the metal parts being joined.

Flow Temperature: Brazing alloys have a range of flow temperatures, depending on their composition. The flow temperature is the temperature at which the alloy becomes liquid enough to flow and fill the joint between the metal parts being joined.

Wetting: Brazing alloys are designed to wet the surfaces of the metals being joined, which means that they form a strong bond with the metal surfaces. This is important for creating a strong and reliable joint.

Corrosion Resistance: Some brazing alloys are specifically designed to be corrosion-resistant, which means that they can be used in environments where corrosion is a concern.

Ductility: The ductility of brazing alloys refers to their ability to deform without breaking. This is important for ensuring that the brazed joint remains intact under stress.

Composition: Brazing alloys are typically composed of a mixture of metals, including copper, silver, zinc, and nickel. The exact composition of the alloy depends on the specific application and the metals being joined.

Cost: The cost of brazing alloys can vary depending on their composition and the application for which they are being used. Some alloys are more expensive than others, but they may offer greater performance or durability in certain applications.

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More