Industry Knowledge Extension

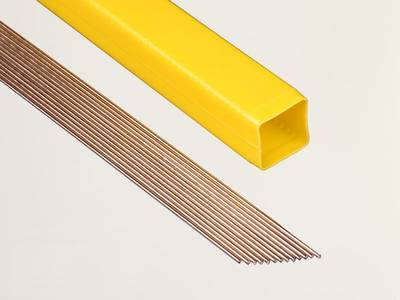

Silver alloys are commonly used as brazing materials due to their excellent wetting properties, low melting point, and high ductility. Brazing is a joining process that uses a filler metal, typically in the form of a wire or a paste, to join two or more metal components by melting the filler metal and allowing it to flow into the joint by capillary action. The following are some common silver alloy brazing materials:

Silver-Copper-Zinc-Tin Alloys (Ag-Cu-Zn-Sn): These alloys are commonly known as silver solders and have a wide range of compositions with melting points from 600°C to 900°C. They have excellent flow and wetting properties and are suitable for brazing a wide range of metals and alloys.

Silver-Copper-Zinc-Nickel Alloys (Ag-Cu-Zn-Ni): These alloys have higher melting points than Ag-Cu-Zn-Sn alloys, typically ranging from 700°C to 900°C. They have excellent strength and ductility and are commonly used for brazing stainless steels and nickel alloys.

Silver-Copper-Zinc-Cadmium Alloys (Ag-Cu-Zn-Cd): These alloys have low melting points, typically ranging from 620°C to 730°C. They have excellent fluidity and are commonly used for brazing copper and brass components.

Silver-Copper-Zinc-Indium Alloys (Ag-Cu-Zn-In): These alloys have a eutectic composition, meaning they have the lowest melting point of all silver alloys, typically around 570°C. They have excellent wetting and flow properties and are commonly used for brazing stainless steel and other high-chromium alloys.

It's important to note that cadmium-containing silver alloys are not used in some industries due to the health and environmental hazards associated with cadmium exposure. In such cases, cadmium-free silver alloys are used instead.

Silver alloy brazing materials are commonly used in various applications where strong and reliable metal joints are required. Brazing is a process of joining metals by heating them to a temperature above their melting point, and then cooling them to create a strong bond between the metals.

The use of silver alloy brazing materials is advantageous because they offer excellent strength, ductility, and thermal conductivity. They are also resistant to corrosion and can withstand high temperatures, making them suitable for use in high-stress applications. Additionally, they have a low melting point, which means they can be used to join metals that have a lower melting point than the brazing material itself.

Some common applications of silver alloy brazing materials include joining copper, brass, stainless steel, and other non-ferrous metals in industries such as automotive, aerospace, electronics, and plumbing. They are also used in the production of heat exchangers, electrical contacts, and various other metal components.

In addition to their physical properties, silver alloy brazing materials can be formulated with different compositions to suit specific applications. For example, alloys with higher silver content have a lower melting point, while those with higher copper or nickel content have higher strength and better corrosion resistance.

Overall, silver alloy brazing materials are an essential component in many industries, providing a reliable and efficient method for joining metal components.

View More

View More

View More

View More